It should be developed for mass production

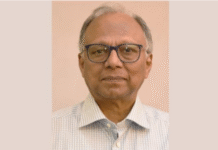

We are delighted by the news of an innovative invention by Dr Mubarak Ahmad Khan—a biodegradable protective gear used by healthcare professionals and others using easily available, natural material—jute and the shell of crabs, lobsters and shrimp. As incredible as it sounds Dr Khan, a scientific adviser to Bangladesh Jute Mills Corporation, has come up with this biodegradable, non-toxic material that can make personal protective equipment (PPE) which can be easily discarded without causing any harm to the environment.

This is a revolutionary invention that can solve the growing problem of toxic waste created by discarded PPEs made of polythene-like material that poses high risks in terms of contamination and environmental degradation. We are already aware of hazardous Covid-19 related plastic waste being discarded improperly that can spread the disease further.

Dr Khan’s endeavour follows his earlier discovery of a jute polymer to make the famous “Sonali Bag” that can replace the environmentally hazardous polythene that is still rampantly used and discarded indiscriminately, causing irreparable damage to water bodies, the ocean floor, aquatic life and the environment in general.

It is exciting news that the scientist has made this PPE with cellulose extracted from jute and chitosan, a natural fibrous material made from the exoskeleton of aquatic creatures such as crab, lobster and shrimp. These are readily available in Bangladesh and the material developed is also cost effective. According to Dr Khan, chitosan has been shown to provide anti-viral immune protection and is a component of vaccines and other drugs. This kind of PPE, moreover, is easier to decontaminate and dispose of as it disintegrates in water within seven days and in soapy water, it dissolves in three minutes, during which most viruses are also destroyed. Thus the potential to use this material for PPEs, which are so cruicial for Covid-19 management, is huge. There are also important implications in terms of marketing this product internationally if it can be produced on a mass scale.

It is wonderful news that already Dr Mubarak has received the approval from Massachusetts Institute of Technology (MIT) and is about to test it at the Shishu Hospital, and he will work with ICDDR,B to develop the protective gear. The scientist has also mentioned that this material can be used to for packaging purposes and to make shrouds for dead bodies.