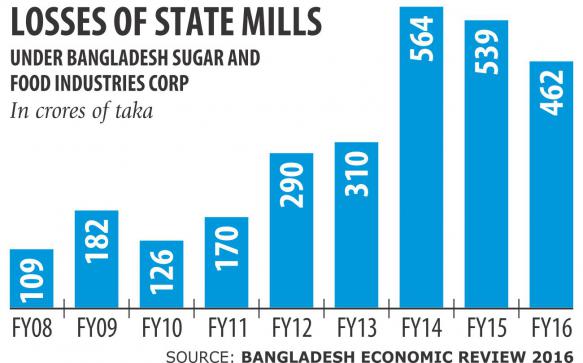

government is set to spend Tk 809 crore to establish distilleries, cogeneration and biogas plants in two sugar mills with the view to turning the loss-making entities into profitable ones, said officials of state-run Bangladesh Sugar and Food Industries Corporation. The plants are: Thakurgaon Sugar Mills and North Bengal Sugar Mills in Natore. “Only sugar production cannot make a mill viable. Proper utilisation of by-products of sugar can make a mill profitable,” said AKM Delwer Hussain, BSFIC’s chairman-in-charge. This is going to be one of the highest ever investments by the state in sugar mills since the country’s independence in 1971. At present, Bangladesh can meet about 5 percent of its annual demand for sugar through domestic production. It has to spend more than Tk 5,000 crore a year to import sugar to meet the annual domestic requirement of over Tk 20 lakh tonnes, according to estimates. BSFIC, which helps the government keep the sugar price stable, has the capacity to produce 2.1 lakh tonnes of sugar a year. But in the absence of adequate amounts of sugarcane, its 15 mills cannot fully utilise the production capacity. The sugar mills’ production continues only for 2-3 months in a year, with factories posting losses at the end of the fiscal year, according to officials. The corporation reduced its losses to Tk 462.39 crore in fiscal 2015-16 from Tk 539.7 crore a year earlier, according to Bangladesh Economic Review 2016. Only Carew & Co, which has a distillery, is in the black. The reason being, the mill uses by-products of sugar to make ethanol, Hussain said. By establishing cogeneration plants, sugar refineries, bio-gas and bio fertiliser plants, these two mills will be able to improve their balance sheets. “We will be able to run mills throughout the year after diversification,” he said, adding that the additional electricity to be generated from the cogeneration plants would be supplied to the national grid. The bio-gas to be produced at the plants will reduce the demand for furnace oil and thus its imports, Hussain said, adding that each sugar mill requires about 20,000 litres of furnace oil a year. “Bio-fertiliser to be produced here will also improve soil fertility.” Under the plan, the government wants to install machinery to produce 300 tonnes of sugar daily through sugar beet, establish a 6-megawatt cogeneration plant as well as machinery to refine 200 tonnes of sugar a day at the Thakurgaon Sugar Mills by investing a total of Tk 485.62 crore. The BSFIC expects to provide 3MW of electricity to the national grid after meeting the requirements of the Thakurgaon mill. A chilling storage facility to preserve 18,000 tonnes of sugar beet will also be constructed. Established in 1958, the sugar mill at the northwest district bordering India has 1,524 tonnes of sugar production capacity. Most of the machinery of the mill has become old and requires replacement. As a result, the government in July this year approved the plan to diversify its activities. The green light to diversify the activities of NBSM at a cost of Tk 324.18 crore came in June this year. NBSM was established at Natore in 1933 with the daily sugarcane crushing capacity of 1,220 tonnes. Later, the capacity was increased to 1,500 tonnes. Over time, the efficiency of the mill has eroded for lack of renovation and modernisation, according to BSFIC. The diversification and modernisation plan for NBSM is similar to Thakurgaon Sugar Mill with one exception: it will not install machinery to make sugar from sugar beet, according to BSFIC. The corporation wants to complete the expansion project by December 2018, Hussain said, adding that more funds will be provided if the two mills perform well. BSFIC has 18,000 employees and five lakh sugarcane farmers are directly and indirectly linked with the sector, according to Hussain. Source: The Daily Star

government is set to spend Tk 809 crore to establish distilleries, cogeneration and biogas plants in two sugar mills with the view to turning the loss-making entities into profitable ones, said officials of state-run Bangladesh Sugar and Food Industries Corporation. The plants are: Thakurgaon Sugar Mills and North Bengal Sugar Mills in Natore. “Only sugar production cannot make a mill viable. Proper utilisation of by-products of sugar can make a mill profitable,” said AKM Delwer Hussain, BSFIC’s chairman-in-charge. This is going to be one of the highest ever investments by the state in sugar mills since the country’s independence in 1971. At present, Bangladesh can meet about 5 percent of its annual demand for sugar through domestic production. It has to spend more than Tk 5,000 crore a year to import sugar to meet the annual domestic requirement of over Tk 20 lakh tonnes, according to estimates. BSFIC, which helps the government keep the sugar price stable, has the capacity to produce 2.1 lakh tonnes of sugar a year. But in the absence of adequate amounts of sugarcane, its 15 mills cannot fully utilise the production capacity. The sugar mills’ production continues only for 2-3 months in a year, with factories posting losses at the end of the fiscal year, according to officials. The corporation reduced its losses to Tk 462.39 crore in fiscal 2015-16 from Tk 539.7 crore a year earlier, according to Bangladesh Economic Review 2016. Only Carew & Co, which has a distillery, is in the black. The reason being, the mill uses by-products of sugar to make ethanol, Hussain said. By establishing cogeneration plants, sugar refineries, bio-gas and bio fertiliser plants, these two mills will be able to improve their balance sheets. “We will be able to run mills throughout the year after diversification,” he said, adding that the additional electricity to be generated from the cogeneration plants would be supplied to the national grid. The bio-gas to be produced at the plants will reduce the demand for furnace oil and thus its imports, Hussain said, adding that each sugar mill requires about 20,000 litres of furnace oil a year. “Bio-fertiliser to be produced here will also improve soil fertility.” Under the plan, the government wants to install machinery to produce 300 tonnes of sugar daily through sugar beet, establish a 6-megawatt cogeneration plant as well as machinery to refine 200 tonnes of sugar a day at the Thakurgaon Sugar Mills by investing a total of Tk 485.62 crore. The BSFIC expects to provide 3MW of electricity to the national grid after meeting the requirements of the Thakurgaon mill. A chilling storage facility to preserve 18,000 tonnes of sugar beet will also be constructed. Established in 1958, the sugar mill at the northwest district bordering India has 1,524 tonnes of sugar production capacity. Most of the machinery of the mill has become old and requires replacement. As a result, the government in July this year approved the plan to diversify its activities. The green light to diversify the activities of NBSM at a cost of Tk 324.18 crore came in June this year. NBSM was established at Natore in 1933 with the daily sugarcane crushing capacity of 1,220 tonnes. Later, the capacity was increased to 1,500 tonnes. Over time, the efficiency of the mill has eroded for lack of renovation and modernisation, according to BSFIC. The diversification and modernisation plan for NBSM is similar to Thakurgaon Sugar Mill with one exception: it will not install machinery to make sugar from sugar beet, according to BSFIC. The corporation wants to complete the expansion project by December 2018, Hussain said, adding that more funds will be provided if the two mills perform well. BSFIC has 18,000 employees and five lakh sugarcane farmers are directly and indirectly linked with the sector, according to Hussain. Source: The Daily Star